woodworking homemade shopmade craft

Camera Tripod

I built a camera tripod. I have one already however it is cheap one and doesn't work well, i.e. too small and weak in construction. A few days ago I used it putting on some low table, but I tangled it to flop down on the floor. Fortunately I could save the camera by catching. I decided to get a tough tripod. I checked on the net but good one is in good price indeed. Therefore I at once started building a tripod.

I found that many people build such tripod on net, but they are overseas mainly, not Japanese ones. They use fine material such as furniture wood like maple, ash and so on. I do not have good material but 2x4 or plywood only. Therefore I designed the tripod in simple construction and enough durable.

I started the work by cutting 1x4 1820 mm into 3 pcs. of 600 mm each.

Next I cut each in thin sticks, i.e. outer 2 pcs. and inner a little thicker one.

The points to contact the floor are shaped triangle.

The small parts are cut out from 1x4.

Sanding all the parts on the belt sander.

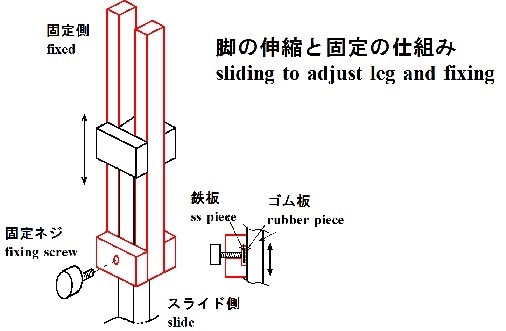

Stand is assembled. Height is freely adjustable and fixed by the screw. I installed a small piece of ss plate and rubber cushion to prevent inner wooden leg damaged.

The legs can be adjustable in length by the simplest mechanism. This mechanism is easy to make and strong. I thought to put the rubber feet or covered by ss sheet at the points to put on the floor, but I use this only indoor. Therefore I didn't.

This is the central base to which the legs are mounted, and the part to fix the central rod at any height. I lined on the material board.

Above parts are cut on the band saw, and finished by sanding

I spraied by clear varnish every part including ones not shown here, such as camera mount, lower construction to regulate opening of the legs. Finally all the parts are assembled.

This is the completed tripod. Max. height is around 1800mm, and min. around 600mm. It is enough strong, and easy to use, as I expected.

Camera mount. Of cause I can set panning and tilting freely. If one touch mechanism which can freely set panning and tilting by one knob or lever, it is more convenient. But so far I need not. If necessary, I will add later.

Lower part in folded condition. The center hole receives the central rod.

Fixing part to adjust height of the central rod and fix by screw knob.

Legs are assembled with the central base by screw.

The part explained above, i.e. to regulate the legs not open too much. I do not know the name of this. Anyway center hole receives the central rod when folded.

As explained above, the legs are adjustable in lengs and fixed. Each fixing screw does not damage the sliding part as small rubber pad is mounted with each screw.

Folded to be compact.

index