woodworking homemade shopmade craft

|

from 2016-03-20 woodworking homemade shopmade HOMEMADE SCROLL SAW2

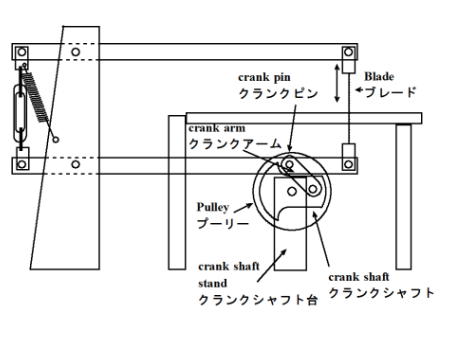

I cannot leave the home made scroll saw, I decided to complete my scroll saw which has been left half way. So far, the latest unit is best as it vibrate least, stroke is longest, and the blade does not swing back and forth. However, the blade brakes so frequently, and I could not solve this problem. Now I think I found the cause of this trouble. I think total rigidity of the construction is not enough. The upper and lower parts of blade holder moves completely synchronously as the feature of this unit. However this causes very strong impact to the blade resulting cut. To prevent this trouble, the total construction must be rigid perfectly. It would take much time to solve this problem, but I need the scroll saw. Therefore, I will complete for the time being the previous unit, i.e. parallel arms mechanism unit. Many amateur wood worker build this parallel arm mechanism machine. This mechanism is easy to build. On Youtube etc. many people show how this mechanism works fine. I suppose there may be a lot of failures behind of the video screen. I assembled the components again and tried to operate. Of cause the unit does not work properly. Strong vibration is caused because of many reasons as mentioned later.  However this trial was out of question. The problems to remove are: The following is the mechanism of this unit.  I have to solve the followings: 1) Motor rotation speed is too high. At this time I use individual motor unit which is made for the wood lathe. The pulley of scroll saw is too small for this motor resulting too high speed movement of the arms. Therefore this pulley must be larger. 1) Blade stroke is too large. Therefore crank circular diameter must be reduced. 2) Shaft hole of the crank arm is too lose. This part is made of wood and the hole is enlarged by vibration. Therefore I change the crank arm to soft steel. Also I will use the bearings at the shaft between pulley and crank to avoid vibration at this part. 4) Connecting shaft of crank and crank arm is loose. If possible, I use a small bearing at this position. 5) All the rotating components must be rigid. 6) Parallelism of all the shaft, i.e. pulley, crank, crank arm, lower arm must be perfect. 7) Pedestal of pulley is too weak to support this movement.  The above is improved scroll saw. It looks same as previous one, but total vibration reduced dramatically, As shown on the following movie, it can cut good. I improved the above mentioned points. I could succeed to make this unit useable well. And it will be better if total construction is made more strong. Many wood workers use their shop made scroll saw on their videos. Mine is not satisfactory yet, but useable. I will improve the latest model as soon as possible. This is my new decision. Article Index Return to Home |